TEAM

Thermal process technology

We are your competent partner for all aspects of gas applications, from basic research to fuel flexibility of different combustion processes. We are happy to support you in optimizing energy-intensive processes with our test beds.

New burner test stand

Our industrial furnace can be operated with a firing capacity of up to 1 MW at a maximum furnace chamber temperature of 1.250 °C. The total installed output is 2.3 MW, so that regenerative burner systems or burner systems in alternating operation can also be tested. It is also possible to simulate a thermal load in the combustion chamber which allows for different temperature conditions and heat loads. Due to the size of the furnace chamber, material and component tests can also be carried out in addition to tests on firing systems with regard to their emissions, performance characteristics or fuel flexibility.

Technical data

- Furnace chamber temperature: up to 1.250 °C

- Burner capacity: 1 MW single firing | 2.3 MW total installed capacity

- Clear furnace chamber: 2.400 mm x 1,800 mm x 1.500 mm

- Atmosphere: Variable furnace pressure control up to 50 Pa

- Natural gas supply: Medium and high pressure up to 4 bar with up to 100 m3/h | low pressure up to 100 mbar with up to 70 m3/h

- Hydrogen supply: Up to 1,1 MW/ 350 m³/h and 2,7 bar

- Combustion air supply: up to 185 mbar and up to 1,800 m3/h

- Compressed air supply: 16 bar

- Thermal load: up to approx. 250 kW

- Electrical power supply: 400 V, 64 A

OPTISOS® 2.0

Optical probe systems: Evaluation and assessment of thermal process systems

The OPTISOS® 2.0 probe offers you the opportunity to look live into your running process, to monitor, evaluate and analyze it. Detect changes in your system before problems occur with the latest analysis technology from the DBI Group.

We enable condition analyses in the visible spectral range, detect heat sinks and determine temperature distributions inside the system and on the product.

Operating conditions

- Furnace chamber temperature up to 2.000 °C

- Pressure range from high vacuum to overpressure operating conditions

- Various inert gas and furnace atmospheres

- Safe to use in dusty, corrosive or heavily contaminated firing

Advantages

- Two viewing angles (0 and 90) for maximum viewing range

- 64° HFoV image aperture angle for both cameras

- 2592×1944 pixel maximum resolution

- 60 images per second maximum frame rate

- Wide-area thermography with high accuracy (1% at > 1.000 °C,

relative accuracy of 1.2 K) - Access opening diameter of only 40 mm required

- Continuous monitoring of process and system

- Predictive planning of downtimes and maintenance

- Control of previously invisible process steps

- Detailed evaluation of your system

Combustion pulsations

System vibration and combustion noise in boilers often have hidden causes. We diagnose your boiler, find the sources of vibration and develop solutions to reduce combustion noise and vibration-induced stress.

Advantages

- Visualization of the flame pattern and combustion chamber condition

- Determination of operation specific frequencies of firing and system peripherals

- Detection and documentation of the excitation of (ab-)normal vibration behavior

- Evaluation of the system status and identification of critical excitation frequencies

- Assessment in the event of a fault or damage

- The system evaluation is based on the regulations VDI guideline 3842, DIN-ISO 10816 and DIN EN 15502.

Special developments

Our innovative technology and more than 30 years of experience in the gas sector enable us to offer you a wide range of services in research and applications in thermal process technology. In addition to our broad portfolio of probe technology, we also offer solutions for inspection, process and flame monitoring that are specially adapted to your system. We look forward to advising you personally!

Advantages

- Products specially adapted to your system

- High process temperatures and pressures (100 bar, 2000 °C)

- Modules for flame monitoring

- Various camera solutions from UV to IR, as well as high-resolution high-speed cameras

- Specially adapted safety devices

- Integration into the control technology

- Hydraulic and mechanical traversing devices

- Continuous monitoring of processes

Your contact to us

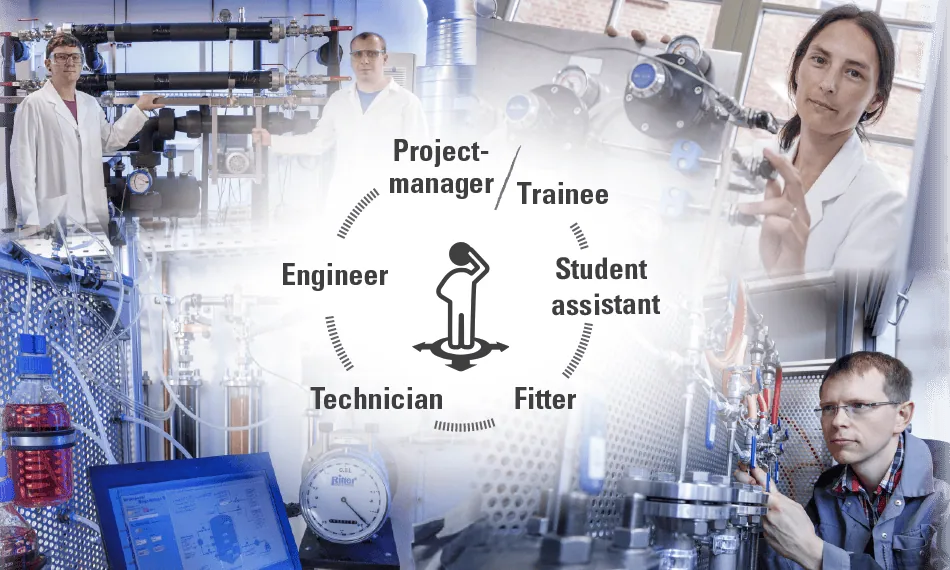

Your career at the DBI Group

Over 150 motivated employees, flat hierarchies and a pleasant working atmosphere are the hallmarks of a committed team. We see ourselves as a reliable employer that supports and challenges its employees throughout their careers. We employ people who are committed to our corporate goals. We are a family-friendly company and expressly follow the legal principles of equal treatment.

The DBI Newsletter.

Receive regular updates from the DBI, tailored to your personal interests.