TEAM

Engineering

From the idea to the system. The engineering team supports you in the area of consulting in all planning phases through to the finished system. With our in-house production, we can build and automate control cabinets and laboratory systems according to your requirements. Furthermore commissioning and process optimization can be carried out at the customer’s premises or on site with the help of our precisemeasurement technology.

Fields of activity

- H2 and CO generation/ rWGS

- reforming process

- Power-to-X

- Material use of CO2 and biogas

- Catalytic gas purification

- Synthesis of liquid energy sources (PtL)

Service

Engineering and Consulting

- Concept development

- Process development

- Process simulation

- Basic and detail engineering

- Scale-up (process, reactor)

- Risk assessment

- Permissioning

- Documentation

- R&D

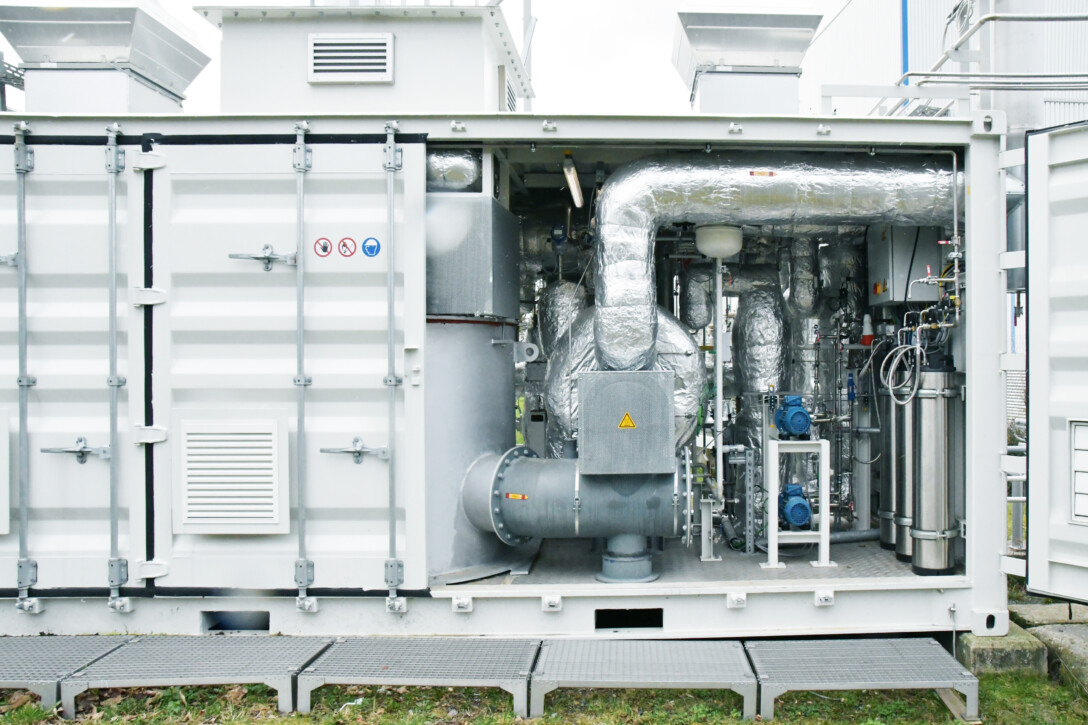

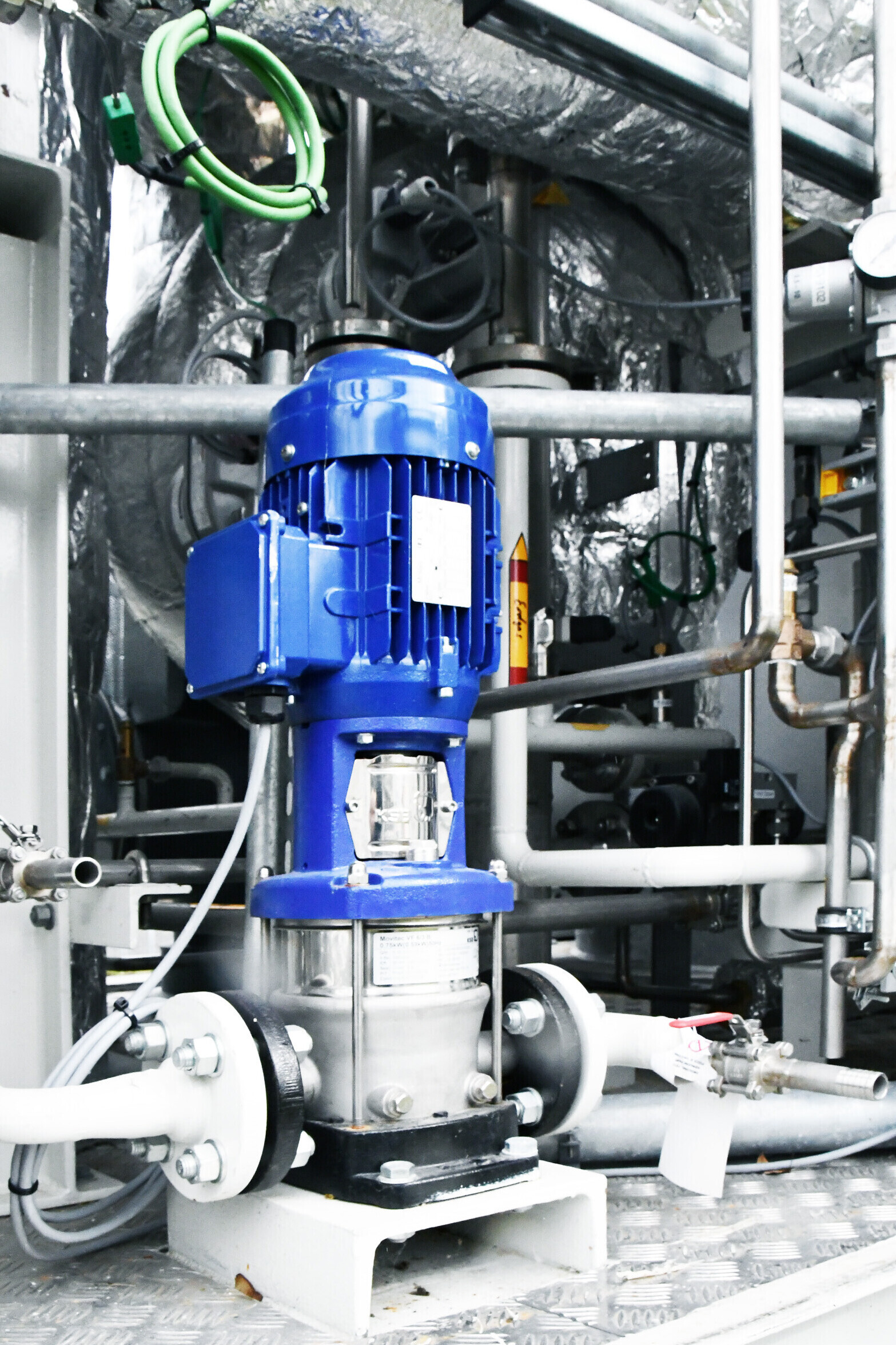

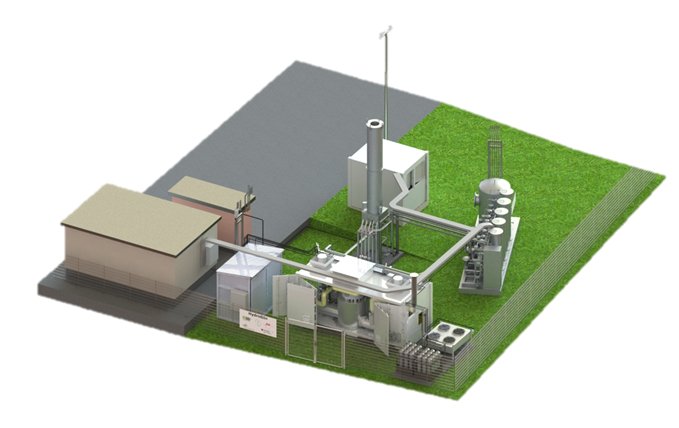

Plant construction

- Planning and construction of laboratory and pilot plants

- Catalyst test rigs (e.g. for reforming, PtX application)

- Batch reactors

- Small series

- Burner development

- Automated process plants

- Interconnection of individual process stages

- Planning and construction of control cabinets

- PLC programming and automation

- Process optimization

Carrying out the experiment

Test environment

- Laboratories with fume cupboard (small systems)

- Technical center (pilot plants)

- Infrastructure (e.g. burner, reformer, PtX application)

- On-site support

Measurement technology

- ND-IR, FT-IR (CO, CO2, IR-active components from < 10 ppm to 50 vol.-%) (online measurement)

- GC (FID, TCD, FPD, MS)

- Chemical/optical sensors (online measurement)

- Exhaust gas measuring kit

Your contact to us

The DBI Newsletter.

Receive regular updates from the DBI, tailored to your personal interests.