Department

Gas processing technology

How can we transfer innovative technologies into the fields of hydrogen production and synthesis (with a focus on PtX: methanol, DME, SAF, …)? This issue is the main focus of the Department of Gas Process Engineering, from laboratory research to real-world application. Our work encompasses feasibility studies, experimental investigations, and process developments, as well as engineering for the implementation of process plants on a container scale.

Furthermore, we conduct detailed R&D within industrial and corresponding publicly funded projects that address specific specialist topics within our expertise. This includes studies on reaction engineering and catalyst screenings, along with associated analytics, technology and process evaluations based on cost estimation methods, and both basic and detailed engineering (including circuit design, automation, and process safety). We have access to appropriate software, laboratories, analytics, and a fully-equipped workshop to fulfill our tasks, allowing us to manufacture smaller plants or prototypes.

Fields of activity

- Engineering

- Reaction Design & Experiments

- Process Studies

- Reforming processes for hydrogen production (Steam Reforming, ATR, POX, dry reforming)

- Fuel cell CHP (component development of H2 peripherals, peak load boilers, purge gas treatment)

- Material use of H2 and CO2 for syntheses (rWGS, SNG, methanol, DME, kerosene, etc.)

- Process development (PtX, BtL, MtJ)

- Process integration (RE potentials and transfer into valuable materials such as H2, methanol)

- Material use of biogas

- Gas treatment, catalytic gas purification

Services

- Concept and feasibility studies

- Process analysis and simulation

- Reaction engineering studies Scientific support / consulting

- Simulation of process engineering equipment (reactors, mixers, heat exchangers, etc.)

- Engineering and consulting

- Plant construction

Engineering & Consulting

- Concept and feasibility studies on the use of hydrogen, biogas and CO2

- Process analysis and simulation of process engineering processes

- Simulation of process engineering equipment (reactors, mixers, heat exchangers, etc.)

- Preliminary planning/concept development

- Basic and detailed engineering of process plants

- Safety analysis and risk assessment

- Approval procedure

- documentation

Labor Scientific Support / Consulting

- Carrying out catalyst tests on systems on a laboratory or semi-industrial scale

- Catalyst screening and kinetic investigations

- Conducting experiments to test reactors, systems, assemblies or prototypes

- Simulation of catalytic reactions

- Scientific and metrological monitoring of experiments or plants Scientific support / consulting on catalytic reactions and reactor design

Plant engineering

- Development and construction of laboratory and demonstration systems and prototypes

- Planning and construction of control cabinets

- Automation of systems

- Commissioning and process optimization of systems

Research & Development

Hydrogen production/utilization

- BioH2 – Joint project: Climate-neutral use of heat and hydrogen production from biogenic residues and waste materials

Duration: 01/2024 – 12/2024 | Funded by: BMWK | FKZ: 03EI5472C - COnnHy – CO2-neutral methane-based hydrogen production

Duration: 08/2021 – 01/2024 | Funded by: INNO-KOM-MF | FKZ: 49MF210058 - H2Giga – Joint project: Technology platform electrolysis; sub-project reduction of innovation hurdles

Duration: 04/2021 – 03/2025 | Funded by: BMWK | FKZ: 03HY101C - HydroGIn – Joint project: Hydrogen generator for the industry

Duration: 12/2015 – 11/2020 | Funded by BMBF/KMU-innovativ/Energy efficiency and climate protection | FKZ: 01LY1410A - Oxy-TCR – Joint project Energy saving in oxy-fuel-fired thermal process plants through thermochemical recuperation

Duration: 04/2019 – 09/2023, Funded by: BMWi/7th EFP | FKZ: 03ET1654B - H₂-Home II – Joint project: Decentralized energy supply with hydrogen fuel cells

Duration: 05/2019 – 08/2021 | Funded by: BMBF/Zwanzig20-HYPOS | FKZ: 03ZZ0751B

Gas treatment

- Pro-SkaO2 – Development of an energy-efficient oxygen separation process using ceramic pellets – Process development and scaling of O2 separation using OSM

Duration: 03/2023 – 08/2025 | Funded by: AiF-IGF 62 LBR / 1 - MethOx – Joint project: Development of a novel precious metal-free and SO2-resistant catalyst for the long-term stable oxidation of CH4, CH2O and CO in the exhaust gas of stationary gas engines

Duration: 06/2021 – 05/2024 | Funded by BMEL | FKZ: 2220NR263B - Emin-koNa – Emission reduction at small wood combustion plants

Duration: 01/2022 – 06/2024 | Funded by: BMWi/INNO-KOM, MF | FKZ: 49MF210144

Power-to-X processes / production of chemical raw materials

- MeFuSION – Joint project: Methanol Fuel-Cell Supplychain Investigation, Subproject DBI: Design, construction and implementation of rWGS module

Duration: 10/2022 – 09/2025 | Funded by: BMDV | FKZ: 16RK14003C - LEUNA100 – Joint project: Continuous production of eMethanol using homogeneous catalyzed synthesis gas conversion, Subproject DBI: Design, Implemention of rWGS module

Duration: 08/2023 – 07/2026 | Funded by: BMDV | FKZ: 16RK14015B - eCO – Synthesis of carbon monoxide by electrocatalytic reduction of carbon dioxide

completed, funded by: SAB | FKZ: 100354357 - COOMet – Collaborative project: Development of a coupled process for the use of CO2 for energy-optimized methanol production

Duration: 03/2017 – 10/2020 | Funded by BMBF/Zwanzig20-HYPOS | FKZ: 03ZZ0726B - Bio-Wert – Collaborative project: Use of biogas plants for the synthesis of chemical products

Duration: 01/2017 – 10/2020 | Funded by: SMWA/Technology funding | FKZ: 100266399 - BioMeth – Joint project: Synthesis of biomethanol based on biogenic hydrogen for use in the mobility sector

Duration: 08/2020 – 12/2023 | Funded by: BMWi/7th EFP | FKZ: 03EI5423A - SYMBOKO – Collaborative project: Synthesis of methanol from biogas with complete carbon utilization

Duration: 08/2021 – 07/2023 | BMWi/7th EFP | FKZ: 03EE5070A - EwOPro – Joint project: Development of the olefins-to-jetfuel process as a highly innovative stage in the production of kerosene from renewable methanol

Duration: 03/2023 – 08/2026 | Funded by: BMWK | FKZ: 03EI3083B - FlexDME – Joint project: Development of a flexibly operating demonstration plant for the production of dimethyl ether from biogas and hydrogen

Duration: 06/2019 – 05/2023 | Funded by: BMWi Energy transition in transport | FKZ: 03EIV121D - Koralle – Joint project: on-site carbon monoxide generation for small and medium-sized consumers from the chemical industry and metallurgy

Duration: 04/2019 – 12/2021 | Funded by: BMBF/KMI-Innovativ | FKZ: 033RK069A

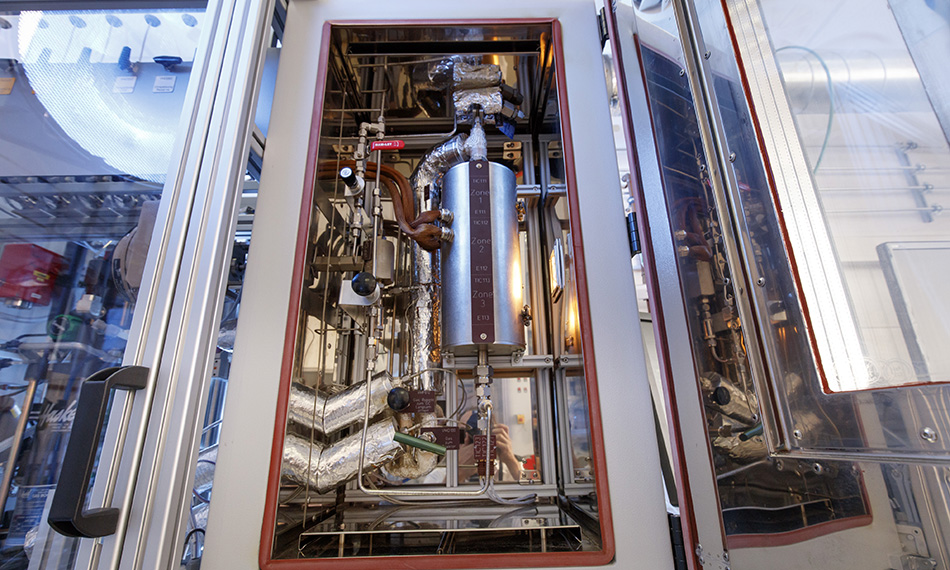

The right equipment for the right solution.

Test stands

- Isothermal, adiabatic or polytropic reaction control

- Catalyst in powder or in technical form such as pellets or honeycombs

- Temperatures up to 900 °C

- Process pressures up to 100 bar

- A wide variety of media possible

(e.g. CxHy, CO, CO2, H2, steam, N2, O2, sulphurous gases) - Reactors for high-pressure syntheses

(pmax from 65 bar, Tmax up to 500°C, 10 ml to 5 l) - Reactors / burners for high-temperature processes

(pmax from 10 bar, Tmax up to 950 °C, up to 0.5 l)

Analytics

- ND-IR, FT-IR – mobile online analysis (IR-active components e.g. steam, CO, CO2, H2, N2, hydrocarbons, NOx. formaldehyde)

- Chemical/optical sensors, mobile online analysis

(CO, CO2, methane, N2, H2) - FID, mobile online analysis (hydrocarbons)

- GC systems (FID, WLD, FPD, MS) for hydrocarbons, sulphur compounds, permanent gas, etc.

- H2 analyzer, mobile online analysis for hydrogen purity

- Exhaust gas measuring kit, mobile online analysis

Software

- Comsol Multiphysics ® (simulation of individual components e.g. reactors, heat exchangers)

- ChemCad (process simulation)

- E-Plan (circuit diagrams, process flow diagrams (R&ID))

- SolidWorks (3D design)

- WinCC Unified, Siemens (automation/PLC programming)

- B&R (automation/PLC programming)

- LabView (automation/PLC programming)

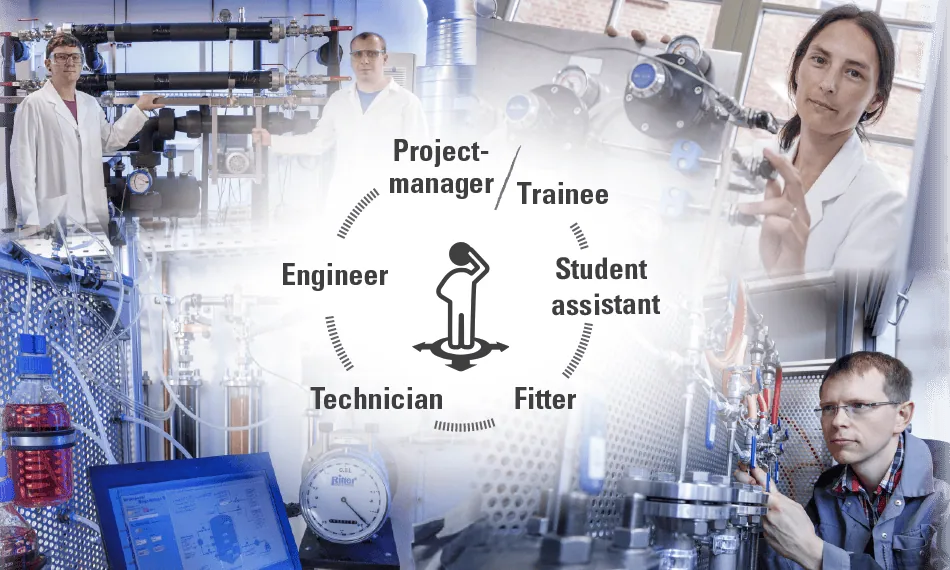

Vacancies

Grow together with the DBI Group. Support the department Gas Process Technology as:

Theses & internships

Your contact to us

Your career at the DBI Group

Over 150 motivated employees, flat hierarchies and a pleasant working atmosphere are the hallmarks of a committed team. We see ourselves as a reliable employer that supports and challenges its employees throughout their careers. We employ people who are committed to our corporate goals. We are a family-friendly company and expressly follow the legal principles of equal treatment.

The DBI Newsletter.

Receive regular updates from the DBI, tailored to your personal interests.