TEAM

Plant design & documentation

The Team Plant Design & Documentation has many years of experience in the design of gas network systems and pipelines as well as the comprehensive, legally compliant and digital documentation of existing plants and pipelines.

We are certified in accordance with DVGW G 493-1 / Group 3 for natural gas.

Plant Design

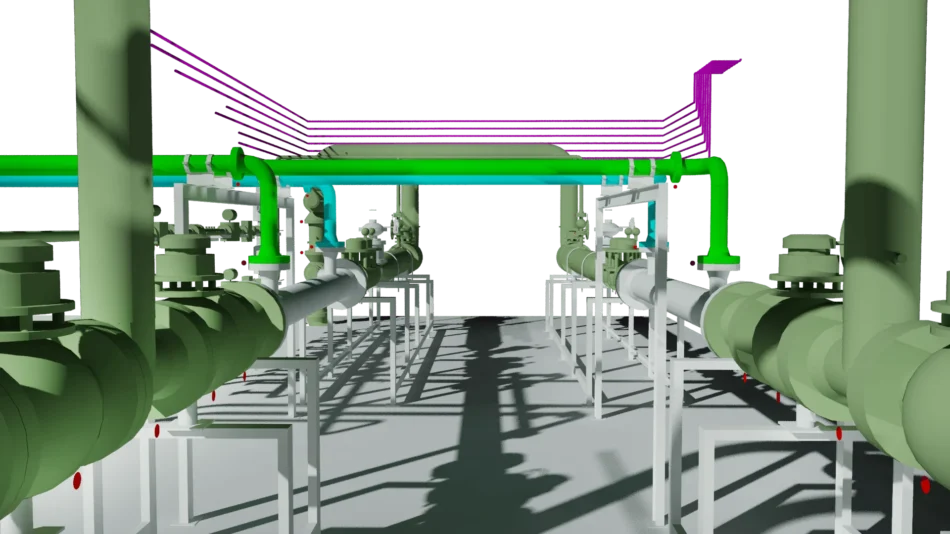

Plant design comprises several key components that ensure that the plants can be operated efficiently, safely and in compliance with DVGW-Regulations. We are looking forward to support you in planning your gas pressure regulating and metering plants, hydrogen feed-in plants and biogas feed-in plants.

1

Design

- Needs analysis

- Site selection

- Dimensioning

- Component selection

- Calculation and design of pipe materials

- and much more.

2

Security and authorization

- Clarification of the legal framework

- Hazard analyses

- Determination of Ex zones and creation of Ex protection documents

- and much more.

3

Technical planning documents

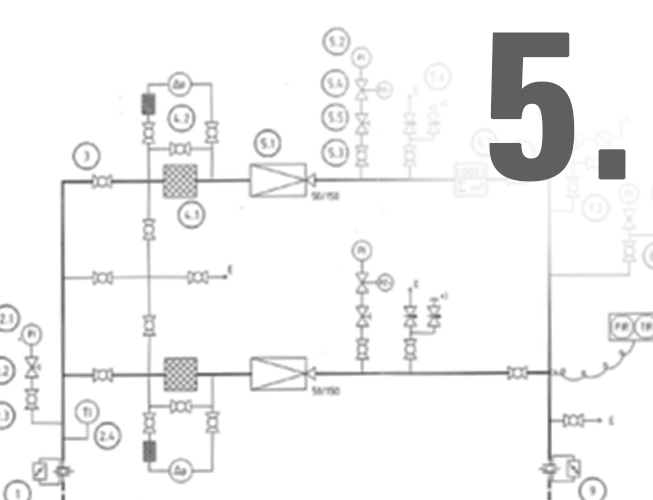

- Process and Instrumentation diagram(s)

- Material and equipment parts lists

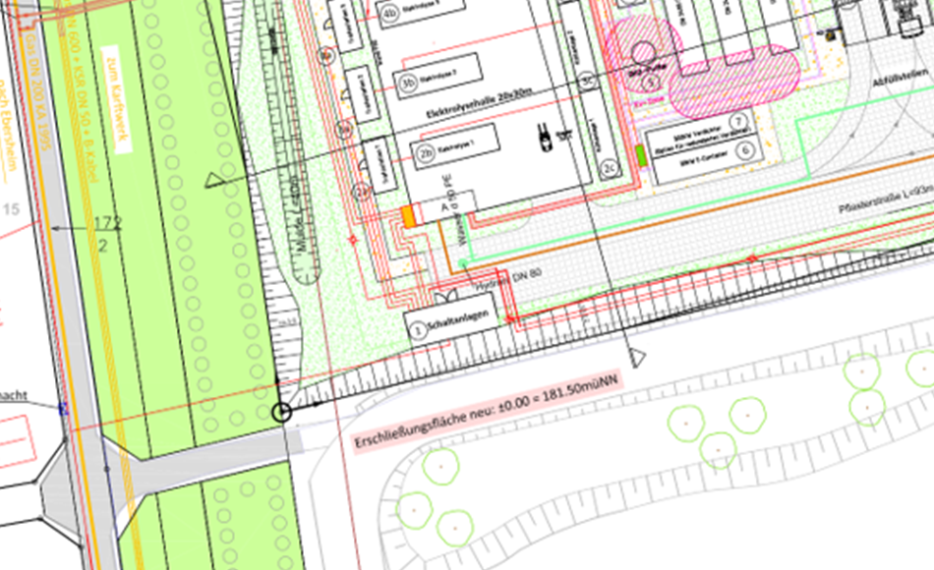

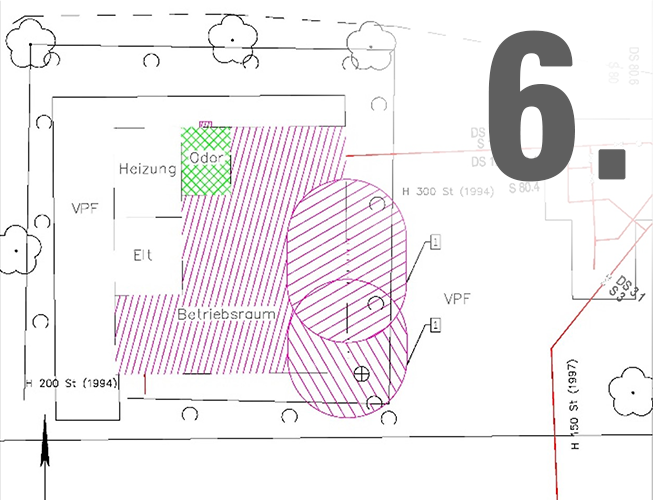

- Plant design in two- and three-dimensional representation

- Pipe classes and tightening torques of flange connections

- Hazardeous Zone calculations and representation

- Cost estimates

- and much more.

4

Contract award and construction

- Preparation of tender documents and specifications

- Obtaining and evaluating offers

- Participation in the awarding of construction contracts

- Supervision and coordination of construction work

- Carrying out construction inspections and recording progress

- Acceptance of construction work and ensuring quality

- and much more.

Digitization

of system and pipeline documentation

Digitization not only enables you to find the documents you need quickly and reliably. Data exchange between different departments is also guaranteed in the digital age. All users – such as inspectors, experts/specialists and system operators – always have the same level of documentation.

“Changes to gas systems or their components and assemblies (e.g. design drawings, system diagrams, parts lists and acceptance or test certificates) must be documented in a suitable form. The documentation, which reflects the current status of the gas system,must be kept available during the entire operating time”.

DVGW G 495: 2014-05

We will digitize all your existing documents for you! We will point out any discrepancies so that these can be rectified in advance and your inspection will be successful.

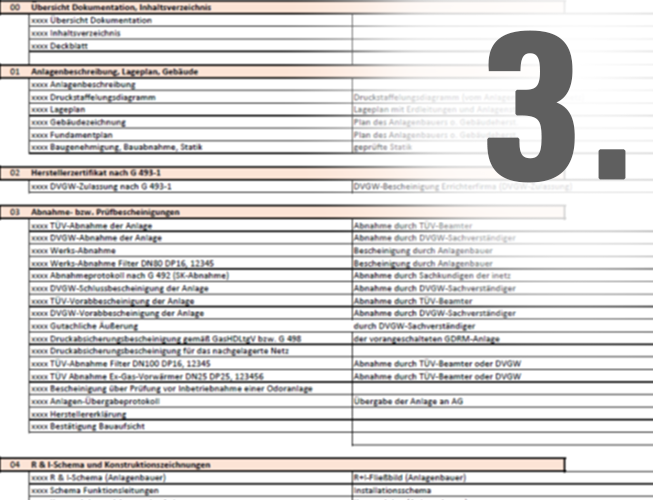

Digitization process

Checking the system files for completeness

The appearance and data structure are very different. In order to meet legal requirements, plant documentation and the necessary documents must be kept constantly available and up to date. Loose-leaf collections from the paper age are not easy to keep track of.

Creation of new line files

in accordance with Gas-Info No. 15 and DVGW Code of Practice G 454 for systems and G453 for pipelines or as specified by the network operator with a standardized register

Creation of difference lists

We create a table of contents and a list of differences according to the network operator’s specifications

On-site recording of the system (image documentation)

The installation is photographed on site and documented in detail in order to record the current condition and create a comprehensive visual and written description for future reference.

Updating documents and certificates

We update the design drawing, Process and Instrumentation diagram(s, parts lists and order missing acceptance and test certificates.

Ex zone calculation

The system operator is responsible for defining the hazardous areas.

- Recording the relevant system data

- Calculation of the spatial extent of hazardous areas

- Designing Ex zones and creating Ex zone plans for gas pressure regulating and metering plants and natural gas filling stations

- Preparation and revision of the explosion protection documents in accordance with DVGW G 440

- Risk assessment of the gas pressure regulating and metering plants

Digitizing and indexing the documents

The documents are digitized by us and recorded in an indexing list.

Preparation of digital data for migration

The digital data is prepared, validated and optimized in a structured manner to ensure a smooth migration to the new system. File formats, metadata and data integrity are checked in the process.

After completion of digitization

- Complete, up-to-date and representative station folders and a standardized structure.

- Electronic availability of files and fast access for various employees guaranteed at all times.

- Complete and legally compliant verification of gas pressure regulating stations.

Related topics

Environment & special projects

We deal with technical specialties and future topics of gas networks and gas plants. One focus is on the transformation of gas networks, the modeling of complex energy systems and the preparation of feasibility studies and potential analyses.

Emissions & life cycle assessments

We advise you on greenhouse gas emissions in the energy sector, carry out carbon footprint calculations and support you in developing a suitable measurement program, collecting emissions data and reporting.

Power-to-Gas

We carry out potential analyses to identify preferred locations and possible applications for power-to-gas (PtG) plants and investigations into hydrogen compatibility and its impact on the gas network and the end customer.

Network projects

We support gas network operators in the creation of specific network models and their performance-oriented optimization as well as in the transformation of their gas networks for the future distribution of hydrogen in order to ensure long-term security of supply.

Your contact to us

Der DBI Newsletter.

Erhalten Sie regelmäßig aktuelle Informationen vom DBI, ganz individuell auf Ihre persönlichen Interessen zugeschnitten.

The DBI Newsletter.

Receive regular updates from the DBI, tailored to your personal interests.