Permeation and leakage tests

What is permeation?

Permeation describes the process by which gas molecules penetrate solid materials. The molecules migrate through the material due to a concentration gradient – i.e. a difference in the concentration of molecules between two sides of the solid. This difference is the driving force for the movement of the gas molecules, which move from the area of higher concentration to the area of lower concentration.

The permeation rate, i.e. the speed at which gas molecules penetrate the material, depends on various factors. These include the specific gas medium, the concentration and pressure present, as well as the temperature, composition and thickness of the penetrated material. Different materials have different permeabilities, as their molecular structures vary and so do the interactions with the gas molecules.

Under constant test conditions – i.e. when factors such as pressure, temperature and concentration remain stable – a constant permeation rate is achieved. This means that the number of gas molecules that permeate the material per unit of time remains constant.

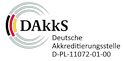

Permeation phases

Adsorption

Absorption

Diffusion

Desorption

Where is permeation relevant?

Permeation is relevant in the monitoring of climate-impacting emissions, such as hydrogen and methane, under the EU Methane Regulation and OGMP. It also plays an important role in the testing of materials for special applications to ensure that materials are sufficiently resistant to gases. In addition, controlling the emission of gases and water-polluting substances is crucial for safety assessments, for example to avoid the risk of explosions caused by flammable gases in enclosed spaces.

Our Services

Testing the permeation

Testing for leaks and leakages

Products: Pipes, pipe-like geometries, pipe connectors, inliners, etc.

As a result, you receive the determined permeation rate and the

specific permeation coefficient or the leakage rate

(for leakage tests). The samples are analyzed using gas chromatography

in our in-house accredited test laboratory.

Measurements in the laboratory

Practical measurements on pipes

or tube-like geometries

- Standard tests

- up to DN100

- Room temperature

- CH4, H2, CO2, etc.

- All materials

Measurements on panels

- e.g. inliner materials, plastics

- Standard tests

- Diameter 105 mm

- Room temperature

- CH4, H2, CO2 etc.

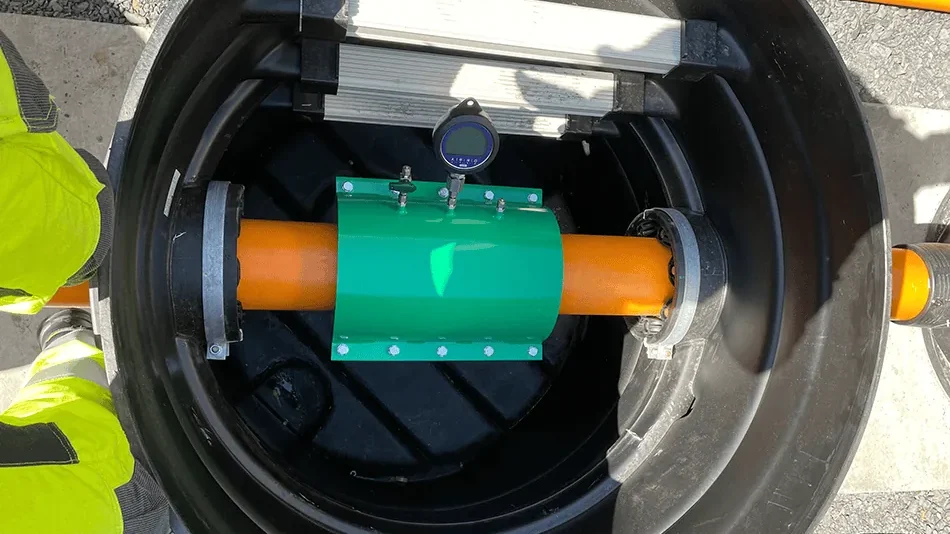

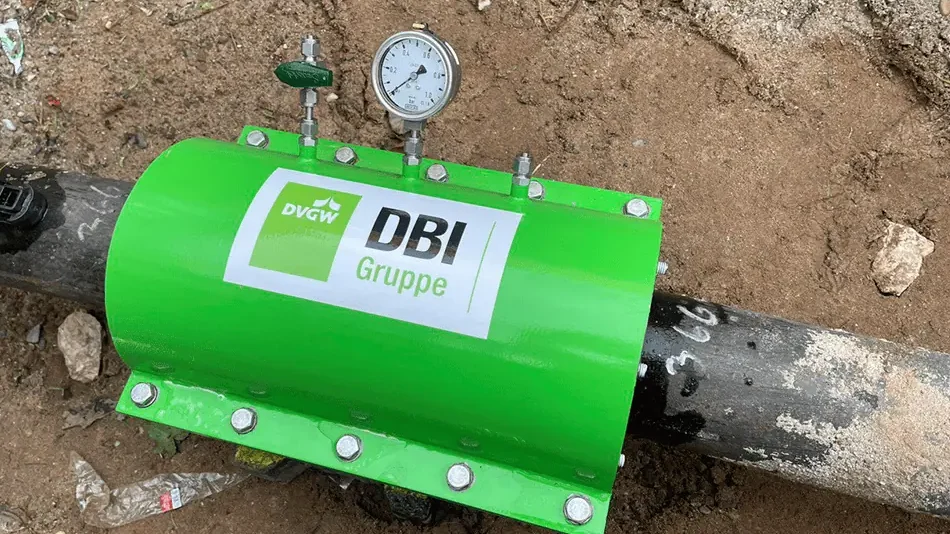

Measurements in the field

Permeation measurements or leakage tests on existing pipes with mobile measuring cell, e.g:

- Leak tests on ductile iron joints after conversion of a pipeline section to H2

- Investigation of pipe joints in a H2 test network

With our measurements we support you, among other things, in

- Evaluation of materials and products with regard to the permeation behavior of different media

- Development of new materials

- Identification of the permeation coefficients for the award of the H2ready test mark

- Determination of climate-impacting emissions (methane and hydrogen)

- Selection of suitable materials, e.g. for the transportation of water-polluting substances

- Estimation of the concentration of flammable gases

Your contact to us

The DBI Newsletter.

Receive regular updates from the DBI, tailored to your personal interests.