TEAM

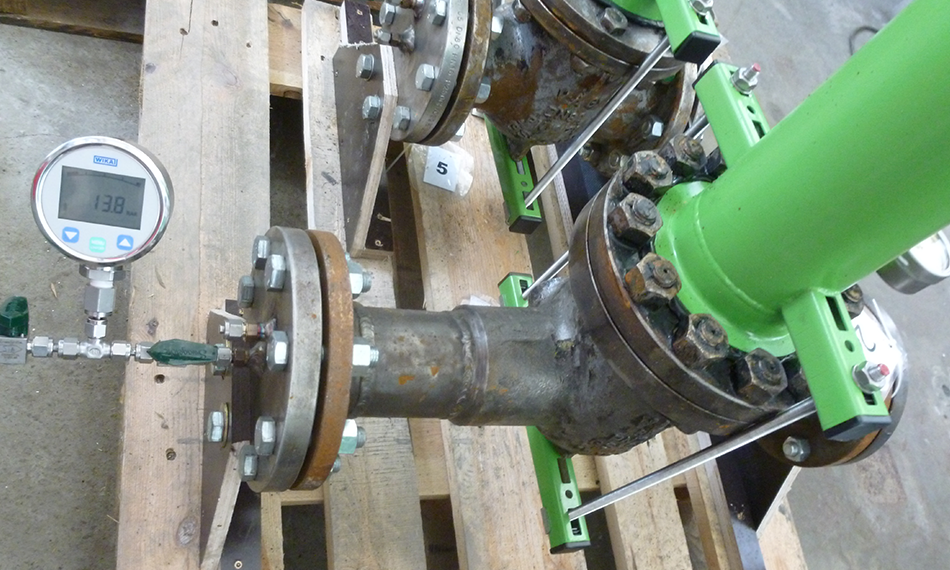

Equipments testing

Equipments and installation systems form an important link in the gas transportation and distribution system. In cooperation with DVGW CERT GmbH, we carry out type examination tests of your equipments and installation systems for the regulated and unregulated sector. Independently of this, we provide you with our testing equipment and experience for special tests.

Testing of equipments for gas and water supply

- Ball equipments according to EN 331, EN 13374 and EN 14141

- Gas shut-off and pressure relief equipments for pressure gauges in accordance with DIN 3590

- Plastic fittings in accordance with EN 1555, EN ISO 17778 and DVGW VP 302

- Water supply fittings in accordance with EN 1074 and EN 12201

- Gas safety fittings in accordance with EN 15069, DIN 30693 and DIN 3586

- Gas pressure regulators in accordance with EN 88, EN 334, EN 16129 and DIN 4811

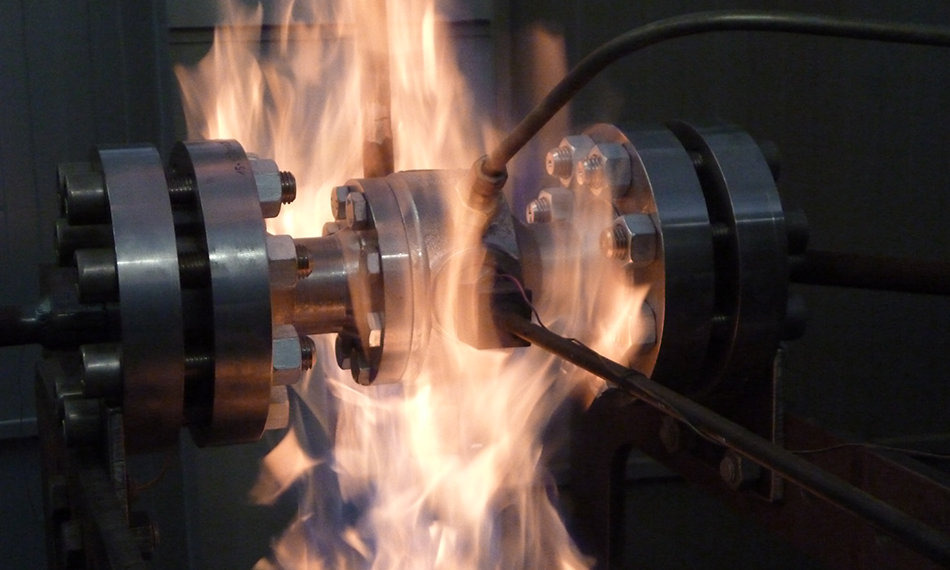

- Fire-safe test in accordance with EN ISO 10497, API 607 and API 6FA

- HTR test DIN EN 1775 Annex A

- House entries according to DVGW VP 601

Hydrogen tests

- Real gas measurements

- Leakage and function

- Permeation tests

- DVGW ZP 4110

- Comparative measurements with other gases

- Long-term stability

- Storage options Autoclave up to max. 100 bar

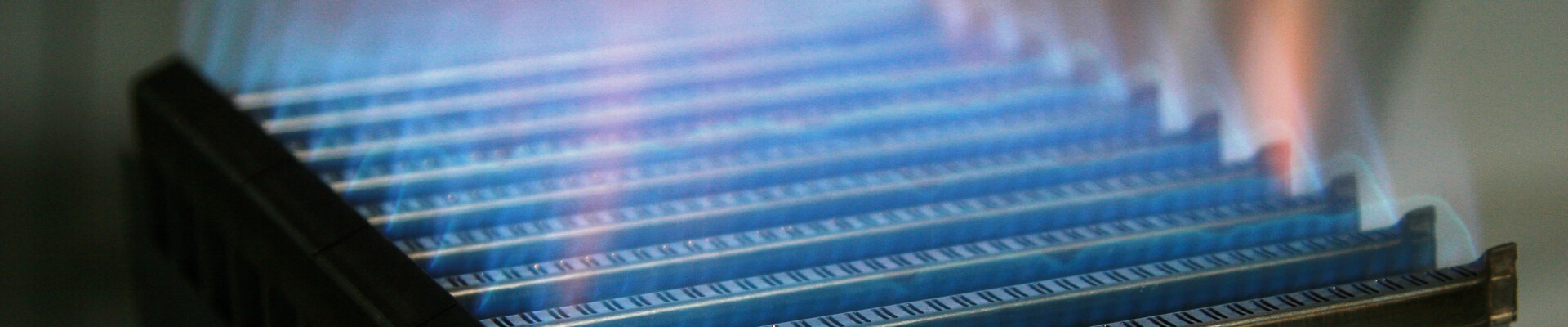

Testing hose/pipe lines and their connecting elements

- Gas safety hose assemblies in accordance with EN 14800

- Metal hose assemblies according to EN ISO 10380, EN 14585-1, EN 16617 and DIN 3384

- Pressure-resistant, flexible hose lines for drinking water installations in accordance with DVGW W 543

- Corrugated gas and water pipe kits in accordance with EN 15266, DVGW GW 354 and DVGW G 5616

- Composite pipe systems in accordance with ISO 17484 and DIN 30655

- Press connector systems in accordance with DVGW G 5614

- Fabric-reinforced plastic inliners in accordance with DVGW VP 643

- Plastic piping systems according to ISO 17778

- Expansion joints according to DIN 30681

Testing of equipments and system parts for the use of liquid fuels in accordance with EN 12514

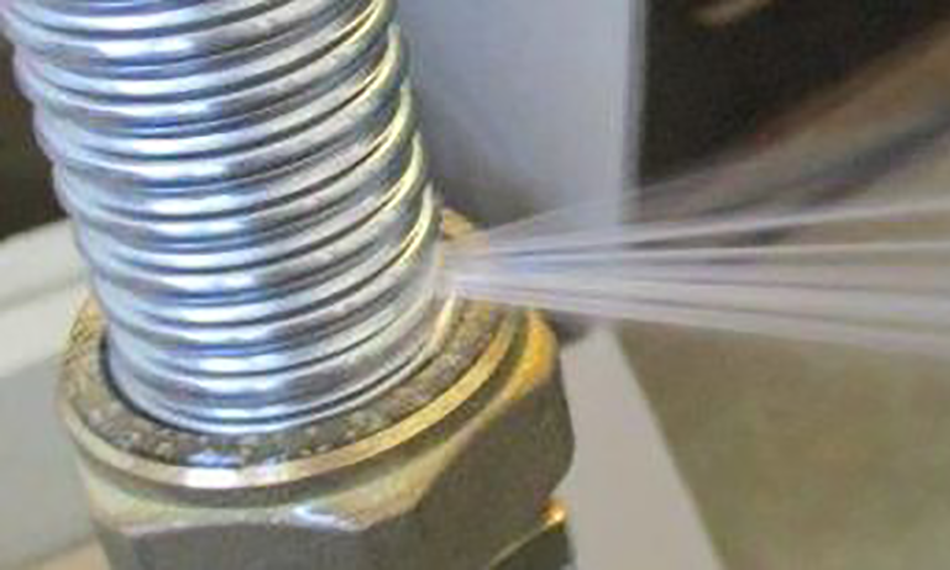

Product-specific special tests

- Long-term suitability of sealing systems

- Load and pressure change with variable increase rates

- hydraulic pmax. 1500bar

- pneumatic pmax 630 bar

- Temperature and climate changes from

-40 °C to +70 °C - creep tests

- Flexibility/bending tests

- Vibration/oscillation tests

- Fire/high temperature tests up to +1100 °C

- Pressure loss and actuation tests

- Fugitive emissions DIN EN ISO 15848

The DBI Newsletter.

Receive regular updates from the DBI, tailored to your personal interests.